Brake Calipers

AUTOMOTIVE

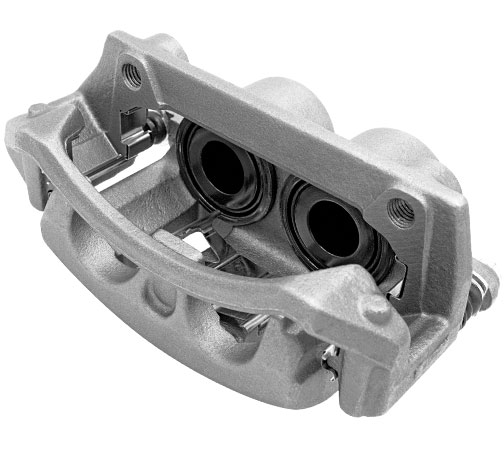

Remanufactured Brake Calipers

Manufactured under the strictest quality standards in an ISO 9001:2015 - registered factory, BBB’s semi-loaded brake calipers are built from O.E. castings to ensure the same fit and function as a new O.E. unit. And, with over 5000 SKU’s, BBB offers the largest selection of sustainably manufactured, semi-loaded brake calipers in the industry, representing over 98.5% coverage. And with our exclusive Job-in-a-Box program, we make installation easier by offering everything needed to do the job right: banjo bolts with new copper crush washers, cable mounting brackets, levers, springs, scrape sensors, and pre-lubed components.

Brake Calipers with TechShield 360®

TechShield 360® is our proprietary, environmentally friendly, electrodeposition coating applied to select brake calipers via an automated submersion process. The TechShield 360® coating bonds with both aluminum and cast iron, resists natural and synthetic brake fluids, and coats calipers edge-to-edge, inside and out leaving all surface areas with a complete protective coating. TechShield 360® meets OSHA and EPA standards and passes a 96-hour salt spray validation test.

CORE RETURN POLICY

Unbroken, complete cores in the original box will receive 100% credit. Broken cores or cores with parts missing will receive 50% core credit only. Dissembled, non-rebuildable, modified or replacement cores will receive zero credit.

The customer is responsible for the condition of the core when returning it to the store. Therefore the store must identify if the core is acceptable before issuing credit. BBB Industries cannot assume responsibility for credits issued for non-rebuildable cores. All cores must be returned in the original packaging to receive credit. Only exchanged cores are accepted for core credit. Core credits are allowed for units in the current Caliper Components program. Cores outside the program will not be accepted for credit. No core credit issued for cores with excessive corrosion, broken, scored bent or worn castings. Partial core credit issued for cores with broken bleeder screws, stripped threads and missing brackets and yokes.

WHAT IS SUSTAINABLE MANUFACTURING?

For 30+ years, BBB has been a pioneer in sustainable manufacturing. An industry that’s part of the circular economy by virtue of what it does -- extend and improve the useful life of critical auto parts.

This expertise has helped us create a precision-tuned process based on superior innovation, leading research, and never-ending process improvements.

We call it Sustainable Manufacturing.

Our sustainable manufacturing process transforms an original part that has lived through its first useful life into a sustainably manufactured part that has a second or third life. Sustainably manufactured products have high-quality standards and are as good or better than new parts. This approach meets the needs of the present without compromising the needs of the future. It’s about conserving natural resources, minimizing negative environmental impact, and doing good for our employees, our communities and each other.