TURBO POWER SYSTEMS

INDUSTRIAL

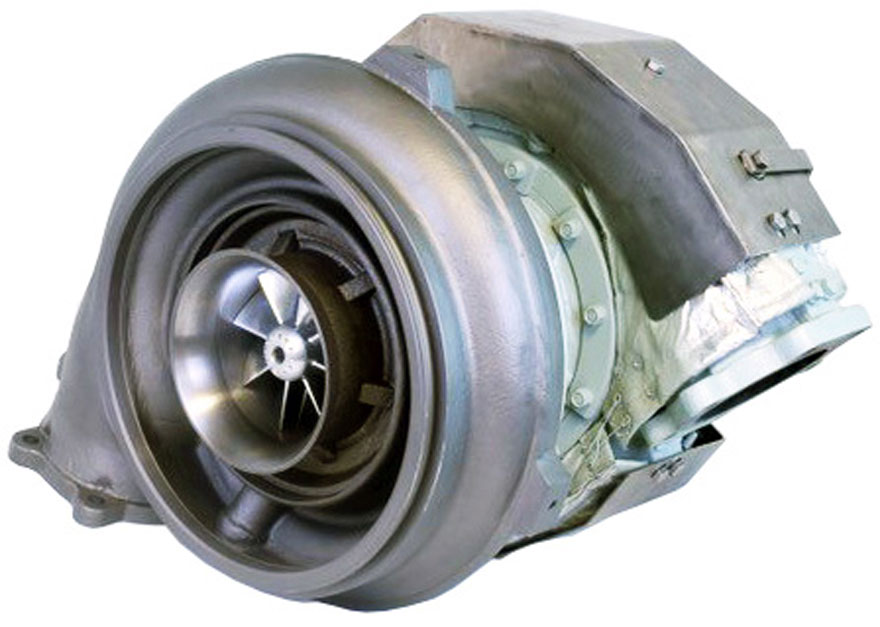

SUSTAINABLY MANUFACTURED INDUSTRIAL TURBOCHARGERS

Designed to meet the efficiency, durability, and reliability demands of complex engines and equipment; while offsetting carbon emissions by 70-90% vs. new.

Our high-performance industrial turbochargers are engineered with premium quality components, precisely calibrated, and extensively tested for operation in harsh environments, under tough running conditions. Turbo Power Systems™ turbochargers are used in all applications including low, medium, and high speed small and large bore, diesel, natural gas, and dual-fuel engines.

Why Turbo Power Systems?

Features and Benefits:

OE-Design

Continuous improvements made to OE designs

Tested

Compressor and turbine wheels are rigorously tested.

Coverage

Comprehensive import and domestic application coverage

Reliability

Reliability throughout the service life of the turbocharger.

Quality

Every unit is completely disassembled, and all components are inspected for Quality Assurance.

Balancing

Balancing is performed at both the Component level and at the Core Assembly level.

When Every Minute Counts,

Count On Turbo Power Systems Turbochargers For Absolute Reliability.

> Cost Savings Over OE for Engine Overhauls

> Increase Your Profit Margin

> Dedicated Sales Support

> Award-Winning Customer Service